We Are Here To Fulfil Your Expectations And Needs.

High-precision CNC turning for shaft parts, solving precision and consistency issues in mass production.

Multi-axis CNC milling that overcomes challenges in machining complex-shaped parts efficiently.

Integrated machining centers eliminating long cycles and precision loss from multiple clamping.

Professional processes enhancing corrosion resistance and consistent appearance quality.

We Are A Professional Hardware Manufacturing Company With Over 20 Years Of Experience.

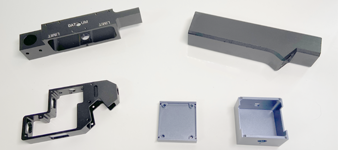

Nimble Tech Manufacturing Co.,Ltd is an enterprise specialized in the processing of all precision machinery parts andthe design and manufacture of tooling fixtures and industrial automation device (non-standard) and integrating design,development and manufacture. Our products widely used in various industry, It included metal parts for automobiles, medicalequipment and healthcare products. We also specialize in plastic injection molding, die casting, molding,extrusion, stampingand forming. We can create each mold or metal part in aluminum, copper, steel and other materials.

As a precision parts supplier, we have equipped with many advance production devices, such as 5 sides machining centerand 5-axis vertical machining center (rom Japan Mori Seiki), High speed CNC machining center, Computer controlled lathe.high speed grinding machine,slow feeding wire-cut machine, advanced microscope, projector, Zeiss CMM, hardness testerand Swiss high instrument etc.

High precision product, steady supply capability and mass production are our advantages. Product precision is up to0.002mm which is admitted in Japan, Germany, Unite states, Canada, Italy and Russian etc.

If you want know more we can send the products introduction and catalogues. Aslo you can visit our website.

We Offer Exceptional Services And Products To Meet Your Needs.

Choosing Nimble Tech Manufacturing Co.,Ltd means choosing a partner who is invested in your success. We understand the importance of time-to-market, cost-efficiency, and quality, and we strive to deliver on all fronts. With a customer-centric approach, we work closely with our clients to understand their needs and provide tailored solutions that drive success.

Our commitment to quality ensures that every part we produce meets the highest standards. We use the latest technology and maintain strict quality control processes.

We understand that time is critical. Our efficient processes and skilled team enable us to provide the fast quotation within 24 hours and deliver your parts quickly without compromising on quality.

Every project is unique. We work closely with our clients to understand their specific needs and provide tailored solutions that meet their exact requirements.

We offer good price without sacrificing quality by choosing suitable processing method. Our goal is to provide the best value for your investment.

Our team of skilled designers, machinists and engineers has years of experience in product R&D, mold design and CNC manufacturing. We have the expertise to handle projects of any complexity.

Our comprehensive manufacturing ability that from initial design to final production, which eliminate the risks of information gaps and product inconsistencies that can arise from switching suppliers, ensuring a more efficient and reliable experience for our customers.

We Deliver Professional One-Stop Service For You

We Value Our Customer Feedback And Satisfaction

After over three years of working with Nimble Tech Manufacturing Co.,Ltd, we can confidently say they are one of the best partners in the industry. Their consistency in delivering top-quality parts and components, even in large volumes, has been invaluable to our business.

When we received the first-off tooling samples from Nimble Tech Manufacturing Co.,Ltd, we were genuinely impressed by the precision and quality. The parts fit perfectly into our assembly process with minimal adjustments needed, allowing us to move into mass production ahead of schedule.

Nimble Tech Manufacturing Co.,Ltd's innovative approach and willingness to collaborate have helped us achieve remarkable results. They truly care about our success.

The technical support provided by Nimble Tech Manufacturing Co.,Ltd has been outstanding. They are always available to address concerns and ensure our projects stay on track.

We brought Nimble Tech Manufacturing Co.,Ltd on board for a highly complex project with tight deadlines, and they delivered beyond our expectations. The attention to detail and level of precision were outstanding, making them our go-to partner for future projects.

Nimble Tech Manufacturing Co.,Ltd's team played a crucial role in turning our conceptual designs into tangible products. Their expertise in CNC machining and rapid prototyping not only accelerated our development process but also ensured flawless execution. They've become an trustworthy partner in our supply chain.

Find Answers To Common Questions About Our Services And Products.

Nimble Tech Manufacturing Co.,Ltd provides a comprehensive range of surface finishing services to enhance the appearance, texture, and functionality of your parts. Our offerings include:

For guidance on selecting the right surface finish or specifying texture details, please refer to our finishes page.

We are committed to delivering high-quality materials and workmanship according to your initial order specifications. Upon request, we can provide full-dimensional reports and material certifications prior to delivery. Any disputes based on a subjective determination shall be brought to the attention of management, they will work in good faith to resolve any issues and ensure your satisfaction, as we value long-term business relationships built on trust and reliability.

While direct comparisons are complex, Nimble Tech Manufacturing Co.,Ltd's prices for plastic injection molds and CNC machined parts are typically 25-45% lower than those of suppliers in North America and Europe. Rather than competing solely on price with other Chinese suppliers, we emphasize high standards of efficiency, quick response times, and expert craftsmanship.

Tolerances depend on several factors such as part size, design geometry, material, surface finish, and manufacturing process. After confirming your order, we will conduct a design review to highlight areas where achieving specific tolerances may be challenging. We encourage you to specify which areas are critical to maintain tight tolerances and which can be adjusted to help save time and reduce costs.

General tolerance guidelines:

Please note that higher tolerances often lead to increased costs. All specifications should be clearly defined in your 2D drawings to ensure precision.

We prefer 3D files in X_T, STP, STEP, STL, SolidWorks, or IGES formats. For 2D drawings, we accept DWG or PDF formats, as long as they contain clear dimensional details and specific manufacturing requirements.

Yes, your design is strictly confidential. We are happy to sign any necessary non-disclosure agreements. Additionally, we enforce a strict no-photography policy in our factory to ensure your product's privacy. We pride ourselves on our long-standing reputation for working with numerous innovative designs while maintaining confidentiality.

We typically respond within one business day. If additional time is required, we will notify you promptly.